by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 3 of 4)

Previous Page

1

2

3

4

Next Page

Another Enlightening Question From Readers

|

Figure 4 - I thought this wall light looked sturdy and cool,

and it only cost $11!

|

The second most prevalent question has been about my choice, methodology, and design for

lighting. The short answer is, "lots of it." There was no real design, per se, to the lighting

other than to hopefully provide more lighting than necessary and then add additional lighting above

the locations where my workbench and drill press will be located. I have always had a hard time

seeing clearly at the drill press.

In the main shop area there are eleven 4-foot long fluorescent fixtures, each with two 32-watt

bulbs generating (claimed) 2950 lumens each. Above the entry door, I installed a circular

fluorescent fixture with two bulbs putting out a total of 2975 lumens. The fixture was a clearance

item that I got for $30, including bulbs. I had a three-light spotlight fixture purchased for a

former house and that was never used. I "repurposed" that fixture and installed it above the future

location of my drill press. The individual spotlights can be turned and aimed as needed. There is

a wall sconce light mounted just inside the double door, and several windows produce a nice bit of

indirect natural light during the day.

|

Figure 5 - Repurposed floodlight fixture throws light on the

stairs and down on the

eventual location of my drill press.

|

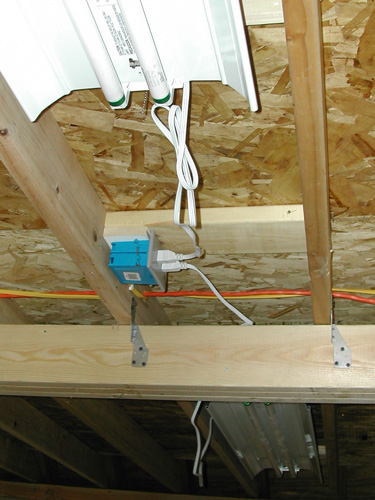

In the big box store there were several options for fluorescent fixtures. My favorite was a

white fixture with a large reflector. Interestingly, they have two versions of the same light. One

includes a pull chain switch, a plug-in power cord, and the "S" hooks and chains you need to hang

the fixture. The other is meant for direct wiring and has no pull chain switch, no power cord, and

no mounting hardware. The direct wire version sells for $10 more. No one could fathom the reason

for this apparent pricing anomaly.

|

Figure 6 – Shop lights mounted and plugged

into a switched outlet assures future flexibility

and saved a few bucks!

|

Internally, both lights are identical. Both have the same electronic ballast, which is important

if your shop gets cold. These ballasts will start up the fluorescent lights when the temperature is

well below freezing. Conventional ballasts often will not work in these conditions.

Eleven lights at a savings of $10 each helped me make the decision to go with the plug-in

version. I wired up electrical outlets in the ceiling on two circuits (zones). The lights are

permanently mounted, no chains and "S" hooks. Both lighting zones are controlled by wall switches

mounted just inside the door. With just two switches I can turn on all the overhead lights in the

shop, but I still have the flexibility of turning off specific lights when not needed by virtue of

the mostly unused pull chain switches.

At some point in the future, I may do a little research into footcandles and lumens and maybe

even borrow or buy a light meter so I can see if my "guesstimates" were correct. For now, though,

the shop and my lighting "design" seem very bright.

(Page 3 of 4)

Previous Page

1

2

3

4

Next Page

Return to Wood News front page