by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

This month:

•

Gimlets Please (Hold the Turkey)

•

Go "Green" In Your New Workshop

•

No Bad Tools

•

Frozen Wood

Gimlets Please (Hold the Turkey)

Heading out to do a little emergency trim repair, my neighbor was helping me carry some tools. I

said, "Grab those gimlets over there, too."

"Gimlets? I don't understand… you want turkey guts?"

"Where I come from we say 'giblets' with a 'j' my friend… I said gimlets," with some emphasis on

the first syllable.

"Ah, gin and lemon juice… sounds good, but can we still fix my trim?"

"No, no, gimlet, from the French word 'guimbelet,' meaning to bore or twist."

My neighbor was unamused. He, like most of us, gets pretty interested when I show him big burly

noisy power equipment and nods appreciatively at finely crafted heirloom hand tools, and even feigns

interest when he sees me doing something as mundane as sharpening. But my little set of gimlets did

not excite him at all. They should have, because in the Down To Earth Woodworking Shop these are

must-have, constantly used tools.

A set of seven

of these indispensible little augers

costs just $17.00, but are the go-to tools for making a quick pilot hole or through-hole for a screw,

a hole for a nail (to prevent splitting), or a starter hole for a larger power-driven drill bit. In

a pinch I've even used the sharp point of a gimlet as a scratch awl. Gimlets will get into places

that drills sometimes cannot, they are precise, they look pretty cool, and they feel great in your

hand.

|

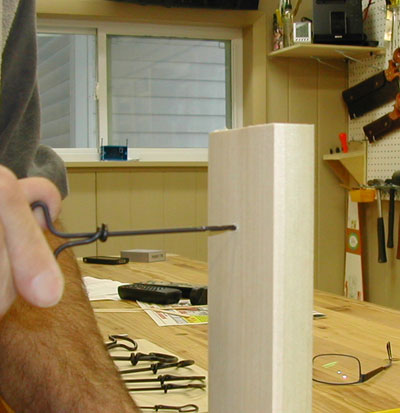

Figure 1 - The sharp point on a gimlet makes

placement for precise hole-starting a breeze

|

And what a timesaver! With one or two pilot holes to make, finding the right size drill bit,

chucking it up, and drilling the holes can take several minutes. Grab a gimlet, place the sharp

point precisely on the mark, and with a couple of quick turns, a perfect pilot hole is made. There

is no need to worry about over-drilling or using depth stops, either. With a gimlet, work can be

very precise.

Installing nine sets of drawer slides in the new shop desk / work bench / glue-up table / clutter

catcher

(click here to see the video series), I used a gimlet to quickly and precisely make pilot

holes dead center in the elongated holes in the slides. I could not have been as precise with a

drill bit or by marking with a pencil and drilling. Nor could I have used a self-centering bit in

the elongated holes. If a power drill had gotten away from me I could have easily drilled right

through the side of the cabinet.

Gimlets are formed with a sharp screw thread on the first quarter- to half-inch. That screw thread

then changes to a familiar auger-cutting pattern. That configuration is why you will sometimes hear

these tools called "auger gimlets" or "gimlet augers." The screw tip pulls the point into the work

effortlessly, and if you continue to turn, the augur grooves enter the hole and with each turn cut

and pull the debris from the hole.

|

Figure 2 - The auger-style threads pull and eject

wood chips as the gimlet makes a hole

|

Well made gimlets,

like those sold by Highland Woodworking, seem to

self-straighten as they enter the work piece, so straight holes are a cinch. I often use the

largest gimlet in the set to make clearance holes for the familiar #8 cabinet pull screws that

accompany most knobs, handles, and pulls. Straight holes make attaching the hardware much simpler.

|

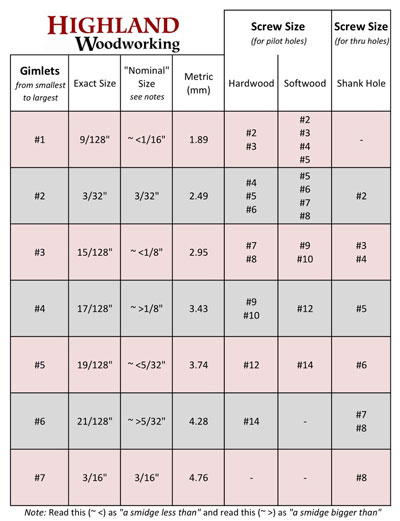

Figure 3 - Click image to enlarge, or

CLICK HERE to download a full-size PDF of the chart

|

Gimlets are sized (nominally) in metric measurements, and for a while I had a difficult time

matching gimlet to screw, especially for pilot holes. You can do what I did for a long time, and

simply hold the screw up to each size gimlet in turn until you find the gimlet that best matches the

screw you want to use. To simplify, though, we have created a chart you can use.

Try them, and in time, the gimlet may become one of your most-used tools as well.

(Page 1 of 4)

1 2

3

4

Next Page

Return to Wood News front page