by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 2 of 3)

Previous Page

1

2

3

Next Page

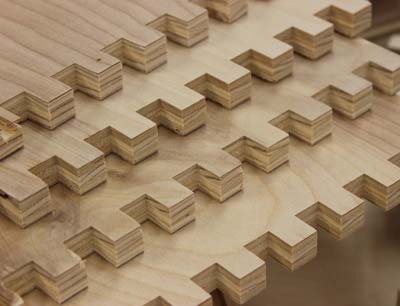

Mobile Sanding Center - Box Joint Drawers Out Of Plywood! (Really?)

Click on any picture to see a larger version.

One might think this is a continuation of the previous section, since the method I used for cutting box joints in the plywood pieces for the drawers of the Mobile Sanding Center is much faster than more conventional methods. Truthfully, it was one part curiosity, two parts experimentation, and one part laziness that prompted me to try this.

|

Figure 8 - The theory is simple - offset

two of the boards the same amount

as the notch size, "gang" the boards

together, and make all the cuts at once.

|

Noodling about, as I am wont to do from time to time, on YouTube, I ran across a video showing how to make a box quickly by ganging the four side pieces, offsetting two, and cutting all the box joint notches at one time.

Doing so successfully requires some compromise and attention to detail. First, once the size of notch is decided, the width of the work pieces should be an even multiple of that size. In other words, if you want to make box joints with 1/2" notches, as I did, the work pieces should be sized as multiples of that dimension, i.e. 4", 6-1/2", or 8" --- not 4-3/4" or 6-5/8".

Second, the four boards need to be clamped to a fence and the first two boards in the stack need to be offset the same thickness as the bit, which of course, is the same thickness as the notch.

As I found out the hard way, the video demonstrator was making a small box and the pieces were relatively short. With a drawer box, the pieces can be quite long. They must be clamped to the fence with considerable force, and the opposite ends of the boards should be clamped together as well to prevent any shifting while the cut is made.

|

Figure 9 - Seven drawers, 28 work pieces,

a total of 360 notches!

|

Still, even with the compromises, the "ganged" method of cutting box joints has advantages. Each board in the "gang" acts as a "tear-out inhibitor" for the board in front and behind it, therefore only one sacrificial piece is needed in front of the "gang" and in back of the "gang." The other advantage is time.

Were I to cut the box joints for the seven drawer boxes for the mobile sanding center on a typical "step and repeat" type jig, I would have had to first make the jig, or bought one, then after set-up and test cuts, I would have made a total of 360 individual cuts… yep, I counted 'em! By "ganging" the boards into groups of four, I was able to make all the drawers with just 90 cuts… a 75% reduction in cutting time.

|

Figure 10 - A few splinters and loose cores in the plywood,

but overall, pretty nice... go ahead, click on the photo and

look at an enlargement. I think you will be impressed.

|

Clamping all the boards together into a nice tight sandwich with the proper offset also seems to virtually guarantee a precise fit. Because the plywood is fragile, particularly at the ends where a notch is cut, there was some cleanup to do after making the box joints, but there was no fitting required. All the joints went together well.

A two-part video showing the entire process is available on the Highland Woodworking YouTube site. The video shows every step, from cutting the blank stock to cutting the joints, from cleaning up the joints to cutting the grooves for the drawer bottoms and more.

(Page 2 of 3)

Previous Page

1

2

3

Next Page

Return to Wood News front page