by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 3 of 3)

Previous Page

1

2

3

Follow-Up Notes – Reader Questions, Comments, and Admonishments

Click on any picture to see a larger version.

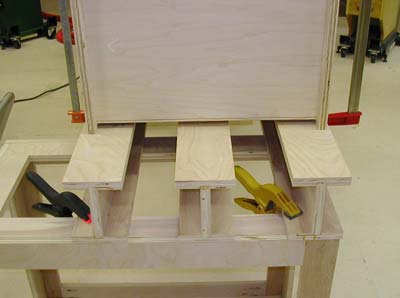

I-Beam Work Supports

|

Figure 11 - Note the spring clamps holding

the I-Beams in place on this recent project.

|

Readers have asked (actually, more like admonished me) why I didn't caution folks to fasten the I-Beam Work Supports to the box frame assemblies in my recent video. I overlooked that detail, and I apologize. Whatever you are doing, you should secure the I-Beams to the Work Supports. If I am doing something heavy-duty, I use small bar clamps. If the work is light and I will move things around frequently, spring clamps work fine. Either way, you want to make sure the I-Beams do not slide around when you are working. Thanks for bringing my oversight to light!

Plywood Dados

|

|

Figure 12 - Is this the right depth?

|

What is the correct depth? Is the old rule of thirds correct? Frankly, I don't know. With just a few cores in today's plywood, does it make more sense to make a deeper dado? After all, the glue is stronger than the wood. Or will the deeper dado weaken the plywood? Sometime in the next few months I plan to set up a torture test of dados in 3/4" cabinet grade plywood. I will cut dados at least three different depths, and we will find out through experimentation which one holds up best. I love breaking things when it is part of the plan… not so much any other time!

An Open Letter To Manufacturers

A couple of months ago I asked that manufacturers try to do a more complete job of providing specifications and data about their equipment for those of us who do not have the luxury of being able to visit a store and get a hands-on look at the tools. The article garnered a lot of commentary, but surprisingly, most of the correspondence was about less-than-stellar customer service. It seems most of our readers don't mind picking up the phone or emailing a manufacturer to get additional information and specifications – what they do mind is surly, ill-informed, or disinterested customer service reps, or, worse, no return phone call at all. As one reader put it, the manufacturers "…never seem to miss an opportunity to miss an opportunity to serve customers…"

Down To Earth Festool

|

Figure 13 - The Zero Halliburton Gold

attache, just $700!

|

There has been some commentary that my assortment of Festool equipment doesn't seem very "Down To Earth." When I hear that comment, I am always reminded of a past business associate/friend that carried a Zero Halliburton case as a briefcase. You know Zero Halliburton cases… top photographers depend on them, in the movies they carry diamonds and nuclear launch codes in them, and they are, well, virtually indestructible --- very classy looking and very expensive.

When I asked my associate why he carried a Zero Halliburton attaché, he said it was because he was cheap. To which I said, "Those things are ghastly expensive." To which he said, "Yeah, but I don't have to replace it every year like any other briefcase… I've had this one over ten years. See? Cheap!"

Next Month in The Down To Earth Woodworker

We will be (hopefully) finishing up the Mobile Sanding Center and actually using this new shop fixture to help build some little projects out of the mounds of leftover wood that seem to have accumulated during the winter. I also did a little mid-year progress check on my New Year's resolutions and found out that I am only about 50% compliant. One cool new project will help correct that situation!

(Page 3 of 3)

Previous Page

1

2

3

Steven Johnson is retired from an almost 30-year career selling medical equipment and

supplies, and now enjoys improving his shop, his skills, and his designs on a full time basis

(although he says home improvement projects and furniture building have been hobbies for most of his

adult life).

Steven can be reached directly via email at downtoearthwoodworks@me.com.

Return to Wood News front page