by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 3 of 5)

Previous Page

1

2

3

4

5

Next Page

Jig Material

Click on any picture to see a larger version.

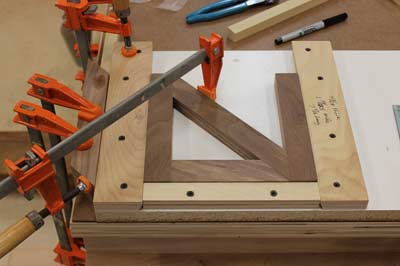

Assembling a special purpose jig during a furniture-building project is usually a slap-dash affair, and the materials used for construction are generally leftovers and scraps. Recently, however, I used laminate-covered 3/4-inch particleboard from the big box store for the base material of a glue-up and assembly jig. This material is sold in various sizes and shapes, from prefab shelves to 4' X 8' sheets, and is cheap, flat, and best of all, glue doesn't stick well to the laminate. Dried drips and squeeze-out can be flicked off easily with a fingernail, putty knife, or a flat screwdriver.

|

Figure 5 - Glue-up jig made on laminate-covered

particle board is flat, smooth, and best of all... easy

to clean!

|

If you haven't worked much with particleboard, there are a couple of caveats to using it as a jig base material. A few cuts probably will not matter, but prolonged sawing of particleboard will dull a saw blade pretty quickly. Some folks change to a less expensive saw blade if they have a lot of cuts to make.

If you use any mechanical fasteners, particleboard likes screws better than nails, and coarse threaded screws better than fine threads. Always drill pilot holes. And be gentle… if you crank down too hard on a screw, the material will give, leaving you with a stripped-out hole. Also, the granular sawdust from particleboard is smelly, nasty, and prolific. Make sure dust collection is adequate and that you wear a dust mask.

Despite these minor drawbacks, laminate pre-covered particleboard material is an inexpensive time and labor saving material for jigs.

(Page 3 of 5)

Previous Page

1

2

3

4

5

Next Page

Return to Wood News front page