by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 2 of 4)

Previous Page

1

2

3

4

Next Page

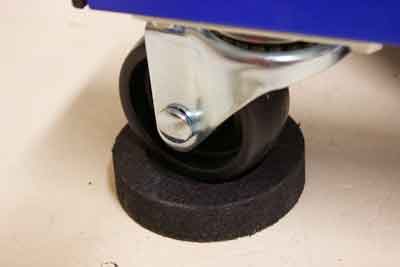

Vibration "Pucks"

Click on any picture to see a larger version.

Do you ever wash clothing? I do. And I am not very good at it. I am convinced that if I keep washing, all my clothes will be the same color; fortunately, judging by the amount of fabric fibers in the dryer's lint trap, the clothes will disintegrate before that happens.

It is said that front-load washing machines are more gentle than top-load machines, are more effective, use less water, and are more energy efficient. I can see the allure, but still I cannot get past their "shaky" past.

I happened to visit a transit warehouse where returned appliances were staged for either disposal or return to the manufacturer. There were US-made front load washing machines stacked three-high by four-wide, running the full 300-foot length of the warehouse. Irate customers returned these machines in droves, and insurance companies and lawyers dealt with grave damage done in houses where these early production machines were installed. All of this was due to excess vibration. In one instance, a homeowner had loaded up the washer, turned it on, and left the house. The machine's vibration caused it to "dance" across the basement floor, pull the hose connections loose, and flood the basement.

A front load washing machine installed in a first floor laundry room vibrated so badly that the vanity mirror in the half-bath on the other side of the house fell off the wall and shattered. These older front load machines were literally "rattling the timbers."

Of course, when a need exists (and sometimes even when it doesn't), a product will soon appear to fill that need. Not long after the American introduction of shaking, rattling and break dancing front load washers, the now-ubiquitous "vibration puck" popped up in appliance and hardware stores. My old-fashioned top-load washing machine doesn't vibrate, but I have some woodworking equipment that does, so I picked up a couple of packs of pucks to see if they might be "re-purposed" in the wood shop.

To be a bit more analytical about it, I measured the vibration of a couple of different machines right at the work surface, then inserted the pucks under the machines' feet and re-measured. Much to my surprise, the vibration at each machine's work surface increased.

Actually, the overall magnitude of vibration increased, but the waveforms changed. The length of vibratory (back-and-forth) movement increased in all three axes, but the frequency, or speed, of the movement decreased slightly. This was puzzling, until a light bulb clicked on (actually it was a slow mental illumination, more like a CFL bulb). I measured the vibration of the cabinet or stand on which each machine was mounted, with and without the pucks between machine and stand. With the pucks under the machines, the vibration of the stands or cabinets was reduced. The pucks were not reducing vibration… they were reducing the transmission of vibration.

Now I understand why front-load washing machine owners swear by these things. The pucks are lessening the vibration transferred to their home's structure. But, since I build shop cabinets and tool stands with high mass/weight in order to dampen vibration anyway, the pucks were unnecessary. I tucked the pucks into a drawer and forgot about them.

Then while I was assembling the JDS dust collector, I wanted to put something under the wheels to assure they didn't move while mounting the top blower/motor assembly onto the frame. They worked well for that purpose, so I said, "Why not just leave them?" (I don't talk to myself often.)

|

Figure 6 - Vibration "puck" under the wheel of the

JDS dust collector

|

So there they are. The pucks are not very thick/tall, so the alignment between dust collector and rolling dust collection bucket required only a minor adjustment. The JDS dust collector is remarkably well balanced and exhibits extremely low vibration, but the pucks effectively prevented what little vibration there was from being transferred to the floor.

Bottom line… if you want to lessen the transmission of vibrational energy, the pucks are useful. If you are expecting them to finally allow you to stand that nickel on edge on your favorite power tool, your money and time is better spent looking for other causes and remedies… they simply will not reduce vibration.

(Page 2 of 4)

Previous Page

1

2

3

4

Next Page

Return to Wood News front page