by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 4 of 4)

Previous Page

1

2

3

4

Pallet Project Safety

Click on any picture to see a larger version.

Have you heard a mother say to a child, "Don't put that in your mouth… you have no idea where it's been!" Working with the wood from a used pallet deserves the adult version of that parental advice.

The only thing that you can know for sure about any pallet is that you know nothing about that pallet… where it has been, what rode atop it, what was spilled or ground into it, or what pathogens lurk amidst this "free" wood.

Pallets are often stored outside. Rain and high humidity can result in mold. Insects, rodents, and birds contribute to possible wood contamination. Pallets can, and often do, contain high bacteria counts. National Consumers League studies showed that 10% of pallets tested positive for E. coli and 3% the deadly Listeria bacteria. In those same tests, almost a third of pallets had high aerobic plate counts indicating unsanitary conditions where bacteria can easily grow.

Pallets are used to ship almost everything, including some nasty chemicals. Broken bags and leaking drums can result in chemical contamination, often deep into the wood of a pallet. Some pretty nasty chemicals were also used in the past to treat pallet wood. Although its use is now prohibited, many methyl bromide treated pallets are still in circulation as are some chromated copper arsenate (CCA) treated pallets. Sometimes pallets (and their contents) are fumigated with toxic pesticides and/or insecticides at a national port of entry to avoid a repeat of the terrible event that brought the emerald ash borer to the U.S. and Canada.

|

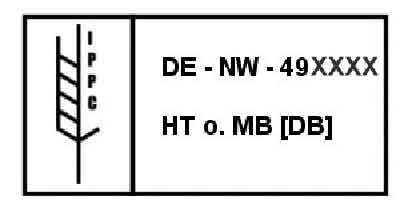

Figure 11 - The IPPC pallet label indicates

country of origin (2 letter country code),

region, and a registration number for the

manufacturer. Below that, the method of

treatment is listed: "HT" for heat-treated,

"MB" for methyl bromide treated,

and/or "DB" for de-barked.

|

Working with pallet wood requires significant extra precaution. A dust mask is always a good idea, but a respirator might be better when cutting pallet wood. Do as much work as possible outside to avoid shop contamination. Make sure your tetanus vaccination is up to date since pallets are full of nails, mostly rusty. Wear eye protection at all times and gloves when handling pallet wood.

Never use pallet wood, even if you think you know its origin and history, in any project that will have direct or indirect food contact. And never, never, never use pallet wood for any project intended for a child (toys, cribs, etc.). Pallet wood is sometimes used to make raised beds or planters for container gardening, but avoid the use of pallet wood for growing any food-producing plant. Most experts recommend that pallet wood not be used to make a compost bin for fear that toxic contaminants will leach into the compost and thus into groundwater or the food chain.

Since pallet wood can contain highly dangerous compounds, a film-forming finish or paint might offer some protection. Some pallet wood aficionados pressure wash their pallets before use.

If all this sounds a bit alarmist… good. At a chemical manufacturing plant I saw a fully suited-up Hazard Response Team diligently cleaning up the spill from a nasty encounter between a forklift and a drum of highly toxic chemicals. After the area and chemicals were contained and the cleanup completed, I watched, horrified, as a worker threw the contaminated pallet onto a stack of used pallets in back of the plant. After a million miles and a few more spills, you may get that pallet. Be careful!

This month's Down To Earth Woodworking Video describes building a wall-hung center for glue-up and clean-up supplies incorporating an innovative shop-made paper towel (or wax paper or anything else on a roll) holder.

CLICK HERE for the links to the Roller-Holder plans mentioned in the video.

---------------------------------------

Next month, join me for a tour of a first class mid-size pallet manufacturing facility (with lots of pictures). Also next month the whimsical bench gets under way and I will explore some ideas for incorporating technology into our woodworking shops and tools.

Editor's Note: A number of readers have requested information about the recent Popular Woodworking University Webinar, "Choosing, Installing, & Grounding a Dust Collection Ductwork System." Readers can purchase Steve's recorded live webinar by visiting Popular Woodworking's "Shop Woodworking" store site by CLICKING HERE.

(Page 4 of 4)

Previous Page

1

2

3

4

Steven Johnson is retired from an almost 30-year career selling medical equipment and

supplies, and now enjoys improving his shop, his skills, and his designs on a full time basis

(although he says home improvement projects and furniture building have been hobbies for most of his

adult life).

Steven can be reached directly via email at downtoearthwoodworks@me.com.

Return to Wood News front page