by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 2 of 4)

Previous Page

1

2

3

4

Next Page

BBCL

Click on any picture to see a larger version.

I really want to do my part and contribute to the growing list of woodworking-specific acronyms. My contribution is "BBCL."

Many woodworkers like to work from plans, and many plans come with a material cut list. Some folks like them, some never use them, and some find them useful as a reference but don't follow them exactly, preferring to "cut to fit" as the project proceeds.

|

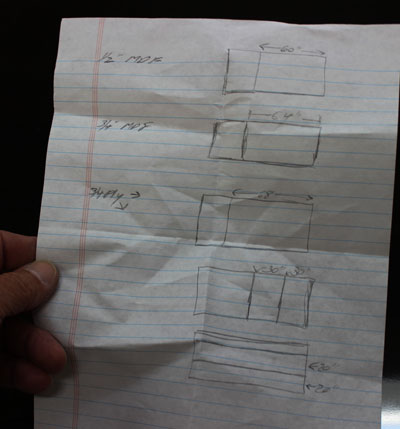

Figure 2 - Nothing fancy... and a little wrinkled

from being folded in my back pocket

|

Only rarely do I make a cut list for the projects I design, and then only to remember grain direction or to help when there are multiple pieces, like when making a stack of drawers.

Lately, though, I have made good use of a different kind of cut list. I call it the Big Box Cut List (BBCL). The Big Box Cut List is a "rough cut" or "breakdown" list for reducing sheet goods into more manageable sizes at the big box store. After designing the outfeed table for my new SawStop PCS (subject of the latest Down To Earth Woodworker video series), I made a list of the sheet goods needed and marked out how I wanted the store to break those sheets down.

The national Big Box stores provide a cutting service and will make one cut on each board or sheet of material at no charge. There is, at least officially, a charge for additional cuts. Fact is, most of the time, the friendly workers at these stores don't charge for a modest number of additional cuts, especially if you are nice, help them move the material around, and don't demand the cuts be overly exact.

That really is not a problem, since "exact" is not the purpose anyway. All you really want to do is get the material down to a manageable size for loading, unloading, and for safe convenient work on the machinery in your shop.

A few tips: First, if you are having sheet goods cut, chances are the employee will not know, or care, to orient the stock so that splintering occurs mostly on the "bad" face… on a stand-up panel saw, that means having the less-good face facing out, toward the operator. Second, when devising your BBCL, allow at least a half-inch extra (or better, a full inch) so that you can trim off the factory edges and the store-cut edge. Don't bury the plywood bar code(s). Set the pieces bearing the barcode aside as the various pieces are cut and place those on the top of the stack. It will save time and effort in the checkout line. Last, when drawing up your BBCL, pay attention to the "apparent" grain direction and how you want it oriented in your project.

A Big Box Cut List (BBCL) will save time, will make your stock easier and safer to work with, and possibly save your back, back at the workshop.

(Page 2 of 4)

Previous Page

1

2

3

4

Next Page

Return to Wood News front page