by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 3 of 4)

Previous Page

1

2

3

4

Next Page

The Ultimate Pallet Wood Project - Part 1

Click on any picture to see a larger version.

It was going to be a joke… a play on words. I intended to counter the seven thousand "Use Pallet Wood to Make a [fill-in-the-blank]" videos on YouTube with my own "Use Pallet Wood To Make A… Pallet" video. But after visiting a rather large pallet manufacturing facility and doing a fair bit of additional research, I realized that the lowly pallet was a much more involved and frankly serious subject, and that a mere joke or play on words would not do justice.

With the price of wood and pretty much everything else soaring, woodworkers are turning to alternative sources, looking for opportunities to recycle and "up cycle," and pallets represent an often inexpensive or free source of wood. Here are some things you need to know:

Pallets are serious business. There are estimated to be almost 3,000 pallet manufacturers in the U.S. alone, with aggregate revenues of over $15 billion. There are some 2.6 billion pallets in use in the U.S. at any given time, a number expected to grow annually about 3.5%. New pallet production is roughly 1.3 billion units per year.

|

|

Figure 8

|

With double the number of pallets in use than are manufactured each year, there is a thriving market for used pallets, which according to industry sources, make up 60% of sales. Some portion of the used pallet business is a virtual "shadow" economy, and as one industry insider told me, "Anybody with a truck can be in the pallet business in two minutes." Lots of people make a living or supplement their incomes by finding sources of used pallets, collecting them, and transporting them to pallet manufacturers for repair and resale or selling directly to shippers and manufacturers for reuse. As many as half of all manufacturers of new pallets run a parallel business of buying, repairing, and reselling used pallets to their more "price sensitive" customers. There are also "pool" pallet businesses that "rent" pallets to users, manage their inventory, and repair or replace pallets as needed to maintain their rental inventory.

Pallets can be made in almost any size and shape and from a variety of materials, but 96 – 97% of all pallets are made of wood, and the most common size is the "GMA" pallet. The Grocery Manufacturers Association set the 48" X 40" size standard back in the 1970s and this most standard size pallet makes up 27% of all pallets produced. In addition to the GMA pallet, other common sizes are 42" X 42" (chemical pallet), 40" X 48" (military pallet), and 48" X 48" (drum pallet). Custom sizes for specific shipping needs make up about 50% of pallet production.

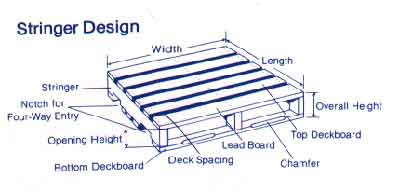

A stringer pallet, sometimes incorrectly called a "skid," is typically constructed with two outboard stringers with a third stringer in the middle. The stringers are notched so that a forklift can enter the pallet from any side. Across the top and bottom of those stringers are nailed deck boards. Typically the end or "lead" deck boards are a little wider than the deck boards in the middle. Bottom deck boards are nailed to the middle and ends of the pallet stringers so as not to interfere with the stringer notch and access by forklifts. Most new pallets are now made from yellow pine, pine-fir, hemlock-fir, ash, poplar, or other less expensive woods, usually based on geographic availability.

|

|

Figure 9

|

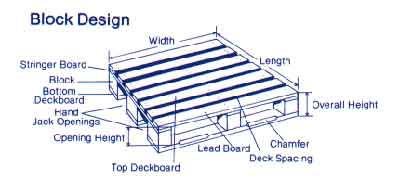

Block pallets are similar to stringer pallets, but the stringers are replaced with blocks, allowing even easier access into all sides of the pallets, especially for hand-operated equipment like pallet jacks.

Pallets came into widespread use in the mid- to late-1930s as a direct result of the invention of the forklift, but pallet usage exploded during World War II with the need to rapidly move large quantities of machines and materials.

Now, as the owner of a local pallet manufacturer explained, "Pallets are the ultimate commodity… all that matters to buyers is price, price, price."

Part of the reason for this is that few manufacturers, distributors and shippers expect to get their pallets back. Pallets are merely a cost of doing business. There are, of course "closed systems" wherein one company might ship a subcomponent to another company, who then sends the empty pallets back to be refilled, but these situations are not in the majority. Most of the time, a pallet that is shipped out just "disappears" into the giant pool of pallets circulating around the globe.

Pallet prices vary from region to region, partly dependent on local wood choices, transportation, energy, and labor costs, and a host of other variables, but a standard new GMA pallet, depending on quantities ordered, might sell for $8 - $12 each.

There are some standards established and some restrictions on pallet manufacturing and use. Pallets shipped out of the country must be either heat or chemically treated to assure there are no living organisms that can "piggyback" a shipment to another country. Likewise, pallets must meet certain standards for the shipment of food, drugs, etc. All in all though, when you scratch the surface of the pallet business, one gets the impression of a wild, wooly, mostly uncontrolled business fraught with waste and inefficiency.

|

Figure 10 - Pallet stamp is key...the "HT"

means this pallet was heat treated, not

chemically treated

|

Some companies that manufacture or re-manufacture wooden pallets are flat-out scary… operations with questionable safety standards and even more questionable business practices. Others, however, are working hard to elevate the stature of the lowly pallet and are on the cutting edge of safety, efficiency, and creativity. I have so far seen little correlation between the size of a company and its relative excellence or lack thereof.

One medium size company I visited was hands-down the best of the bunch, with extreme attention to worker safety, total recycling of no-longer-useable pallet parts, and close attention to quality craftsmanship both in their new pallet production and their remanufacture of used pallets. Next month in this column I will take you on a guided tour of this outstanding facility. Just to "tease" you, there is a very cool machine that disassembles used pallets and sorts the parts, a receiving/sorting area where incoming used pallets are judged, and prominent in the shop is a 5HP SawStop Industrial Table Saw that runs non-stop, eight hours a day. Stay tuned for Part 2!

(Page 3 of 4)

Previous Page

1

2

3

4

Next Page

Return to Wood News front page